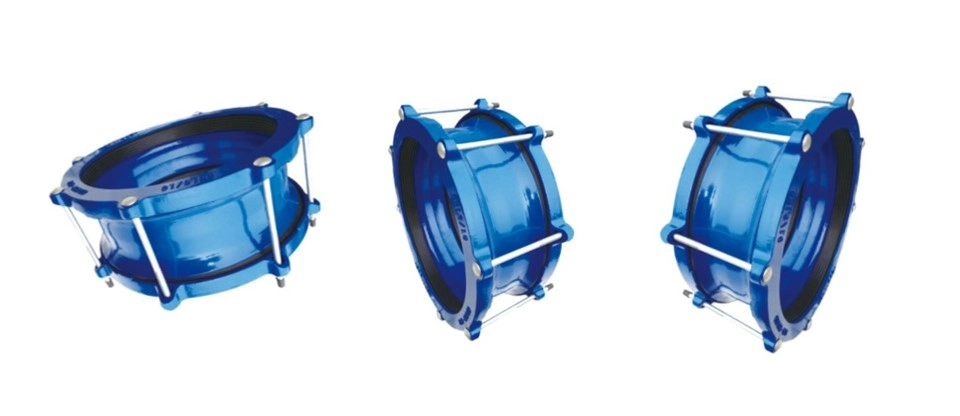

JIS DIN Ductile Iron Universal Coupling for Vavles, Pipes

Basic Info

| Work Pressure | Low Pressure (Pn<1.6mpa) |

| Working Temperature | Normal Temperature (-40°C<T<120°C) |

| Material of Seal Surface | Metal Hard Sealed |

| Valve Body | Casting |

| Standard | JIS/DIN/ANSI |

| Application | Industrial Usage, Water Industrial Usage, Household Usage |

| Certificates | ISO9001 CE Wras |

| End Ring | Ductile Iron Ggg-40 |

| Body | Ductile Iron Ggg-50 |

| Gasket | EPDM / NBR / SBR |

| Bolts & Nuts | Carbon Steel |

| Coating | Epoxy Coating |

| Working Pressure | Pn10 / Pn16 |

| Application Field | Suit for Water, Neutral Liquids and Sewage |

| Transport Package | Plywood Non-Fumigation |

| Specification | DN50-DN700 |

| Trademark | ZHONGHUI or CUSTOMIZED |

| Origin | Tianjin |

| HS Code | 8481804090 |

| Production Capacity | 100000 Pieces Per Year |

Product Description

Ductile Iron Universal Coupling for vavles, pipesNotice:We are a factory with 16 years of experience, we believe that we have absolute advantages in price and quality.

FEATURES

| 1. For STEEL,DI,UPVC,CI,and AC pipes or almost any other rigid pipe material. |

| 2. In the form of wide range (Up to 23mm) couplings,are designed to join pipes of various outside diameters with the same or different nominal bore. |

| 3. PN16 operating pressure. |

| 4. The ability of universal coupling to join dissimilar pipe materials is a bonus feature in both repair or permanent situations. |

| Standards & Specifications | |

| Manufacture | BSEN1563 / EN-GJS(QT)-450-10 |

| Coating | WIS4-52-01 |

| Gasket | EN681-2 |

| Test | EN14525 / BS8561 |

| Working Pressure | PN10 / PN16 |

| Size & Material | |||

| Size Range | DN50-600 | ||

| Main material | Body | CARBON STEEL / DUCTILE IRON | |

| End Ring | DUCTILE IRON GGG-40 | ||

| Gasket | EPDM / NBR / SBR | ||

| Bolts & Nuts | CARBON STEEL | ||

| Coating | EPOXY coating | ||

| UNIVERSAL COUPLING drawings & Dimensions |

| Related product show |

| Tianjin zhonghui Valve Industry is an integrity valve manufacturer, which has its own foundry, matching shop, and assembly line. Our company has passed ISO9001,Wras and CE Certification. Our main products are gate valve, butterfly valve, check valve and control valve, we have been exported to Japan, Singapore, France, USA, Australia and so on, our valves satisfies to the international standard like GB, ANSI/API, DIN as well as client's special specifications. The valves have met with warm reception based on excellent quality, competitive price, good shipment and timely delivery time all over the world. | ||||

| Our products |

| Packaging |

| Certifications |

FAQ

1.Can I have a sample order for valve?

A: Definitely Yes.We welcome sample order to test and check quality. Mixed samples are acceptable.

2. Can you OEM or ODM?

A:Yes, we have a great research & development team. The products can be made according to your request.Please send us high resolutionimages,your logo and other materials needed . We will send you finished files for confirmation.

3. Can you provide the relevant documentation and certificate?

A:Yes, we can provide you with the documentation and certificate you need ,IS09001:2000 international quality system certification,(CE)certification of the European Community, Det Norske Veritas (DNV) factory certification, Lloyd's Register (LR) factory certification, China Classification Society (CCS) quality system certification and the FM and UL certification of the US, Bureau Veritas(BV) ,American Bureau of Shipping(ABS) etc.Of course we can also provide you the test Report; Certificate of Material Analysis; Certificate of Origin; and other export documents which required.

4.How to proceed an order for valve?

A: Step1 let me know your requirements or application. Step 2 We quote according to your requirements or our suggestions. Step 3 Customer confirms the samples and places deposit for formal order. Step 4 We arrange the prodution.

5.What is your terms of delivery?

A: We accepte EXW,FOB,CIF,etc. You can choose the one which is the most convenient for you.

6.What's the package and how do you ship the goods?

A: Usually is wood pallet as your requst. We usually ship by sea.Airline shipping is also optional.

7. How to deal with after sales?

A: warranty time : 24 months from the shipment ; and we will be responsible for all the quality problems. Quality control : High quality mold./Raw materials control/Production process quality control/Final inspection/Water testing (no leaking).

8. What is the average lead time?

A:For samples, the delivery time is about 2-5 days. For mass production, the lead time is about 15-50 days after receiving the deposit payment. we can provide production schedule and related photos every two weeks. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products.If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate our production plan to your needs.

9. Why choose us?

A:We are a verified supplier and creditable company on Made-in-China, Genuine produces with excellent quality and competitive price, we are focusing on the long term relationship with customers, Genuine produces with excellent quality and competitive price. After-Services will be highly-satisfing.